|

Henan Banner New Material Co., Ltd.

|

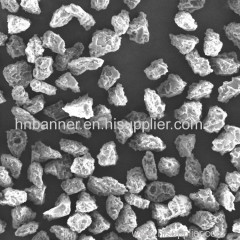

Hot Sale 3 Micron Homothetic Polycrystalline Diamond High Self-Sharpening Monocrystalline Diamond

| Price: | 3.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Homothetic Polycrystalline Diamond Powder, is a kind of new superhard abrasive, which is with similar features to polycrystalline diamond

Homothetic polycrystalline diamond is a new kind of super-hard abrasive, which is made from monocrystalline diamond powder by special processing, is a kind of homothetic polycrystalline diamond powder with similar characteristics with polycrystalline diamond powder. It can be used in most fields instead of polycrystalline diamond powder.

Application of Homothetic Polycrystalline Diamond Powder

For Grinding and Polishing:

Compared with monocrystalline diamond, the homothetic polycrystalline diamond has more cutting edges, a higher removal rate and shorter processing time;

The cutting edges of the homothetic polycrystalline diamond are thin, dense and sharp, the surface of the workpiece after grinding has higher smoothness. Thus, the roughness and grinding process steps can be greatly reduced, and the overall production efficiency is highly improved.

For Diamond Products:

In the process of grinding and polishing, the cutting edge is sharp and dense, and the grinding resistance is small, which can reduce the working temperature of diamond products. Thus, the grinding efficiency is higher, the scratch after machining is finer, and the surface smoothness of the workpiece is higher.

It can effectively grind the impurity particles, large grains and other heterogeneous particles in the material, reduce or even avoid the defects or edge collapse in the process of grinding or polishing.